TAIMA Testing Laboratory - Hardware Strength

By accurately conducting physical performance tests on footwear, we proactively grasp key indicators like durability and mechanical properties. This ensures products meet international standards and quality requirements, providing scientific basis and rapid support for production quality control, raw material incoming inspection, and physical performance verification of developed samples.

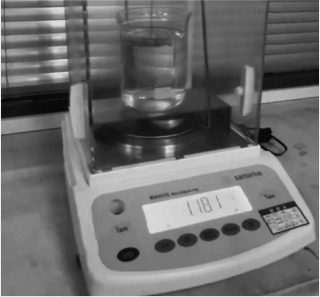

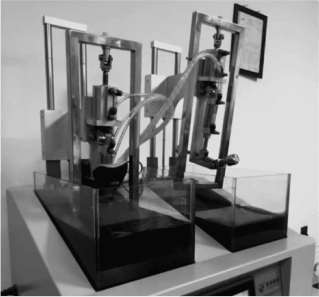

As a benchmark enterprise in the footwear industry, Taima Footwear always takes excellent quality as its core pursuit. We know that in a dynamically changing market, efficient and accurate physical testing is the key to quality control. Therefore, Taima Footwear has built a professional footwear physical testing laboratory, equipped with advanced testing devices such as burst strength tester, DIN abrasion tester, tensile tester, aging tester, high-pressure resistance tester, Martindale abrasion tester, impact tester, whole-shoe waterproof flexing tester, and EN sole flexing machine.

These professional devices not only conduct comprehensive physical tests (such as tensile strength, flexing cycles, and wear resistance) on daily-produced shoes to quickly feedback production quality; but also strictly inspect incoming raw materials to ensure the physical properties of materials like leather and rubber meet standards from the source. Moreover, they provide accurate physical performance data for developed samples, speeding up new product R&D and quality verification. In this way, they fully ensure the process precision and quality stability of each pair of shoes, and bring consumers comfortable and durable footwear experience through technological empowerment.

TAIMA shoes empowers production with technology, gains trust through quality, and continuously leads new trends in the footwear industry.

中文

中文  English

English